Prevention and Control of Pollution

The use of excessive water during production often leads to sewage water and wastes. In order to reduce environmental pollution, we focus on the treatment of sewage water and wastes, and efforts are as follows.

Sewage treatment

- Established class-B industrial sewage technicians.

- To protect the environment, we have introduced UASB “upflow anaerobic sludge blanket reactor” to reinforce our sewage treatment. We use COD instruments to regularly control, inspect, and supervise the quality of sewage discharged by each unit and the effectiveness of sewage-treatment measures.

- For sewage treatment, we have installed a 200-ton sewage facility in Taichung Youth Plant and a 400-ton sewage facility in Taichung Youth Plant 2; both of which meet the regulations on industrial sewage pipelines and discharge.

- The processed sewage meets the regulations for the sewage treatment plants in Dajia.

Processing of wastes

Recyclable: Recyclable materials are processed by recyclers

We have established a long-term relationship with the supplier of cardboard boxes. Old boxes are picked up and reused after the supplier delivers new ones, saving them the packaging material in the process.Reusable wastes such as paper and metal are jointly collected by recyclers for reuse.Wastes discharged during the fermentation process are used to fertilize our lawns and gardens, reducing waste and improving our landscape at the same time. Excessive waste is also sold to fertilizer companies as the raw material for fertilizers, reducing the waste of our company by 120,000 kg per year and increasing our revenue.

Non-recyclable: Removed and processed by certified contractors

Previously, some of our products had to be made with organic solutions, causing concerns for the environment and workers’ health. The site personnel and R&D units then worked together to replaced the solution with water-based products, saving us considerable resources, ensuring workers’ health, and reducing environmental impact. The tablet-making processes changed to water-based procedures include BBT4, CET, and GFT. The Enteric-coating processes changed to water-based procedures include BGT, GBT, and CSTs.

We also use distillation-based recycling equipment and technique to recycle organic sewage through distillation, effectively reducing waste and harmful material and saving the cost of raw material. In 2006 alone we recycled more than 100 tons of solution.

Sewage Treatment Facility

USAB

Distillation Retrieval and Process Equipment

Recycle of Waste Paper

Energy Saving

Energy and water saving measures are in effect in all plants. Water in vacuum pumps and for washing injection bottles are recycled and reused. Water-flow controllers are installed at the tips of all sanitation pipelines. Water-saving sprayers are installed in all washing-rooms at public areas.

66000M3

The water-saving measures save us approximately

66,000 cubic meters of water per year.

The waste water discharged by the 600 RT absorption refrigerator is fully recycled and stored for boiler use, saving the use of chemicals such as detergents and deoxidants as well as soft-water ion-exchange resin. The water-temperature after vaporization is between 50~60℃, reducing the use of boiler fuel, water, and energy.

Energy Saving For air-conditioning, we use heat-exchange systems to force fresh air into the building, and use the low-temperature air to be discharged to conduct latent-heat and sensible-heat exchange, thus saves energy with a retrieval rate of 75%. This reduces the energy-consumption of chillers and boilers as well as the heat-emission of boilers.

For areas requiring less lighting such as hallways, the switch for partial-lighting has been installed to save electricity, and heat-sensors have also been installed for lights placed in areas such as bathrooms, public areas, and hallways.

For central air-conditioning, we use the ice-storage air-conditioning system during low-load (off-peak) hours, during which the chiller makes and stores ice water, and then releases it during peak-hours in daytime for all AC systems, effectively balancing power-consumption of different hours.

Vegetation

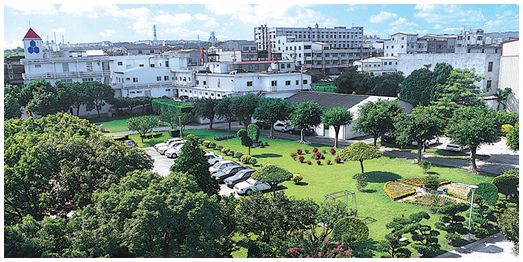

We continue our founder’s concept of a “boundless garden” by turning the environment of our plant into a park and implementing vegetation on our sites.

These efforts not only provide our employees with a beautiful work environment but also leave a good impression in our guests, improving our corporate image.Our sites are covered with flowers, trees, and lawns, and 25% of our sites are covered in vegetation. In recent years we have been encouraging our employees to get creative, including reusing waste or environmental-friendly materials and decorating indoor and outdoor settings with plants. We have successfully created a relaxing and delightful indoor garden with minimum expenses and with employees’ creativity. Our employees’ creative thoughts can be seen throughout the site, and each corner is full of boundless energy and life.

TAICHUNG YOUTH FACTORY

HEAD OFFICE